Cutting Rules

Steel Sheet / Steel Plate for Flexible Die

1. Rotary Die Cutting

2. Flat Bed Die Cutting

There are various types of bases, including magnetic ones, aluminum, and steel.

【What an amazing die!Features of Flexible Die】

●Proficient in Complex Shapes!

Flexible dies excel at reproducing intricate and fine shapes, including challenging R sections that are difficult to produce with conventional Thomson molds.

●Resolving the Blade Joint Problem!

In the conventional Thomson die cutting, there was always a need to join the blade least one point. However, by employing etching and CNC machining, we can achieve a seamless line, addressing the blade joint issue.

●Extremely High Dimensional Accuracy!

Our advanced CNC processing maintains sharpness, achieving a blade height tolerance of ±0.0012" inches (0.03mm). Additionally, some cutting dies guarantee an even more precise blade height tolerance of ±0.0008" inches (0.02mm).

● Dramatic Cost Reduction! Suitable for Small Quantities!

Traditional solid dies and metal stamping dies typically involve high initial costs and are confined to large production quantities. However, with flexible dies, we only need to replace the flexible die on the magnetic cylinder or base. This not only initial expenses but also enables efficient handling of small batch production, making a significant contribution.

Product Specifications

Standard Sizes:15 3/4" x 23 5/8" inch (400 × 600 mm)

Hardness:HRC 50 / 1760 MPa

※Sizes up to

15 3/4" x 78 47/64" inch (400 × 2,000 mm)

- Sample Offer -

▸Thickness

1/64" , 1/32" , 3/64" , 1/16" , 5/64" (inch)

0.45 / 0.5 / 0.6 / 0.8 / 1.0 / 1.2 / 1.5 / 2.03 (mm)

▸Sizes:15 3/4" x 23 5/8" inch (400 × 600 mm)

▸Hardness:HRC 50 / 1760 MPa

Processing Examples with Flexible Dies

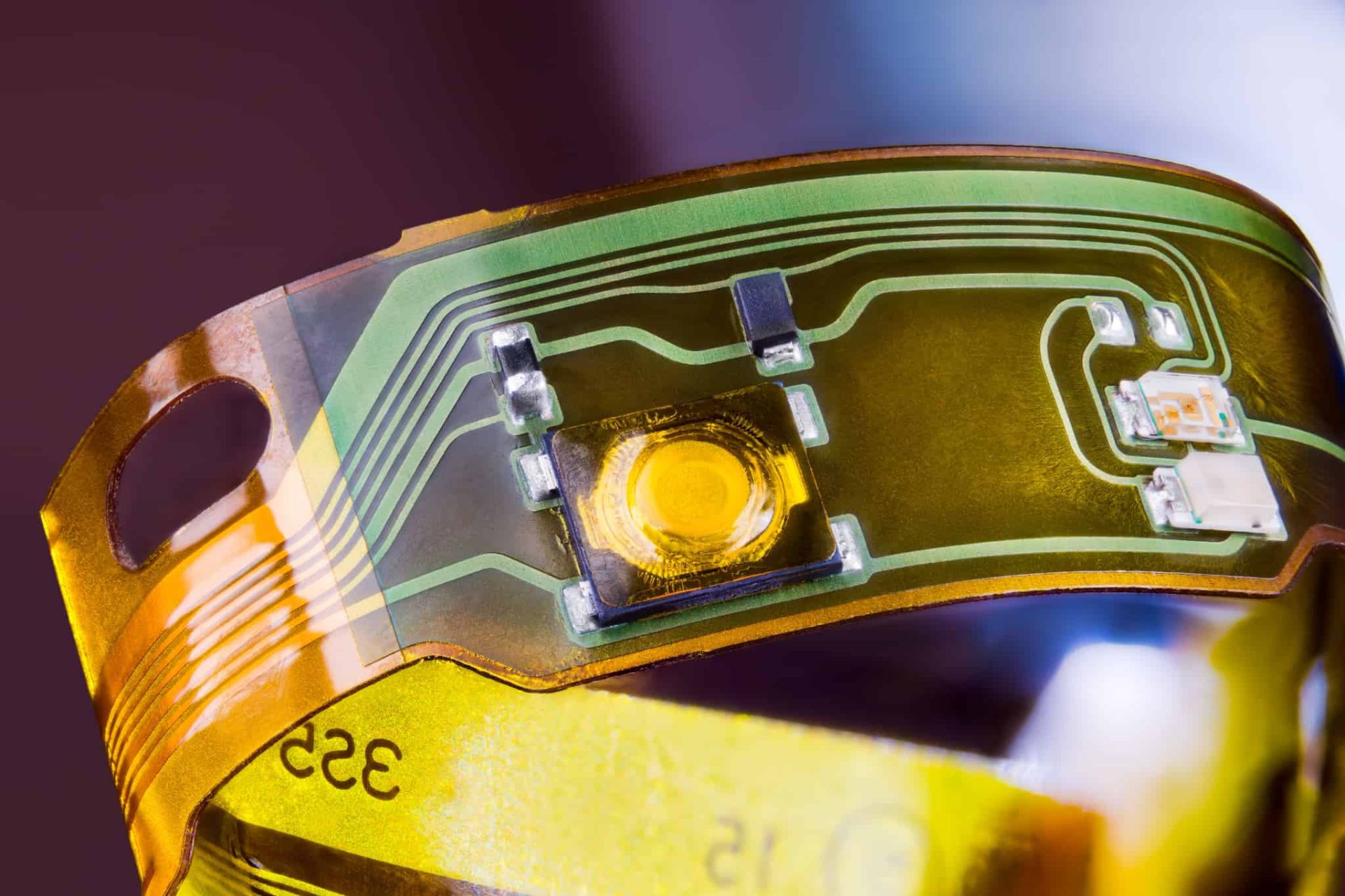

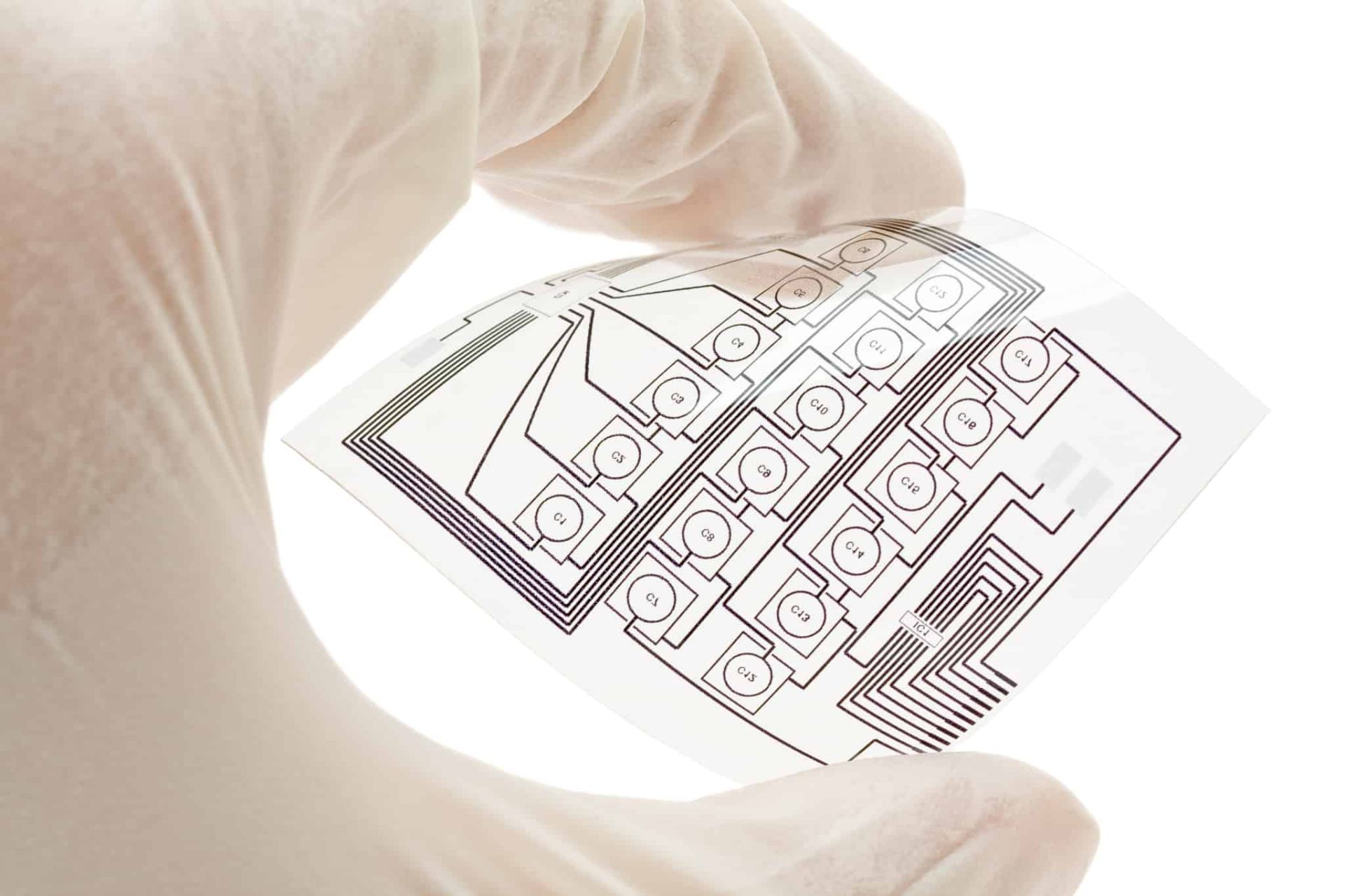

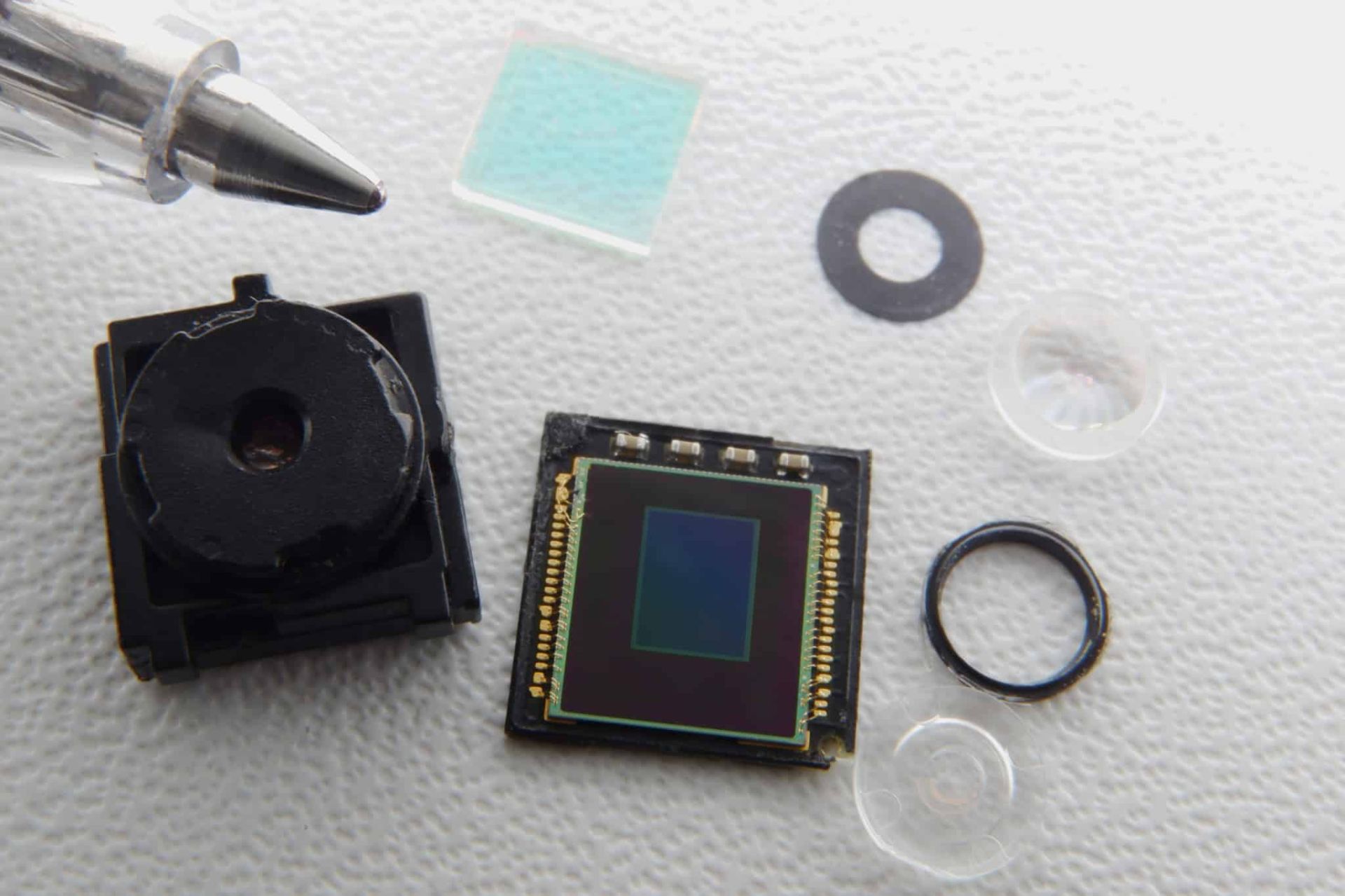

Flexible Die Applications in Electronics & Optics Industry

In the electronics and optics industry, flexible die technology is essential for producing components like double-sided tape,

polarizer films, and FPC. These parts, commonly found in smartphones and smartwatches, demand seamless cutters,

high precision, and efficient roll-to-roll processing.

-

Flexible PCB

-

OCA Film

-

OLED / LCD

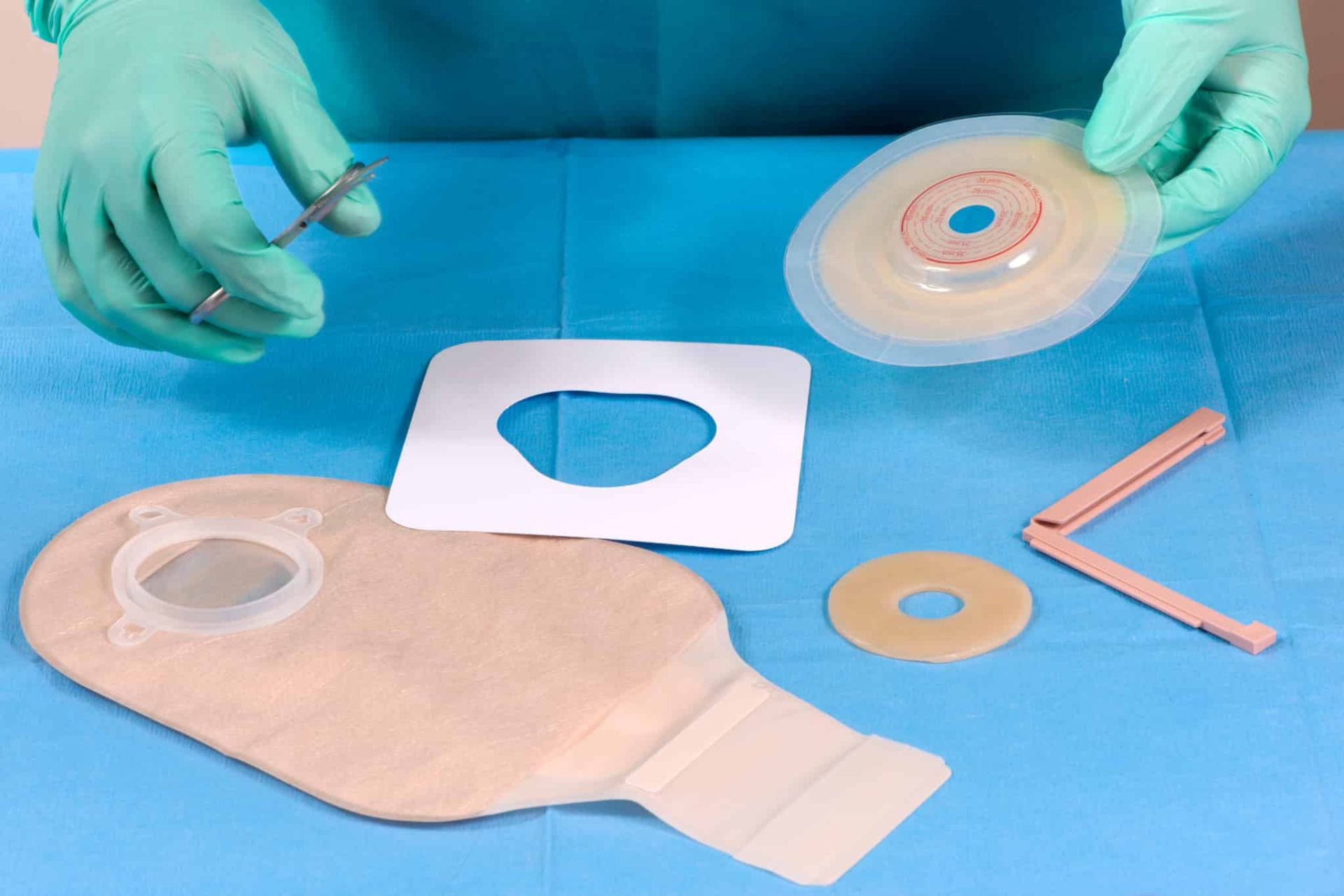

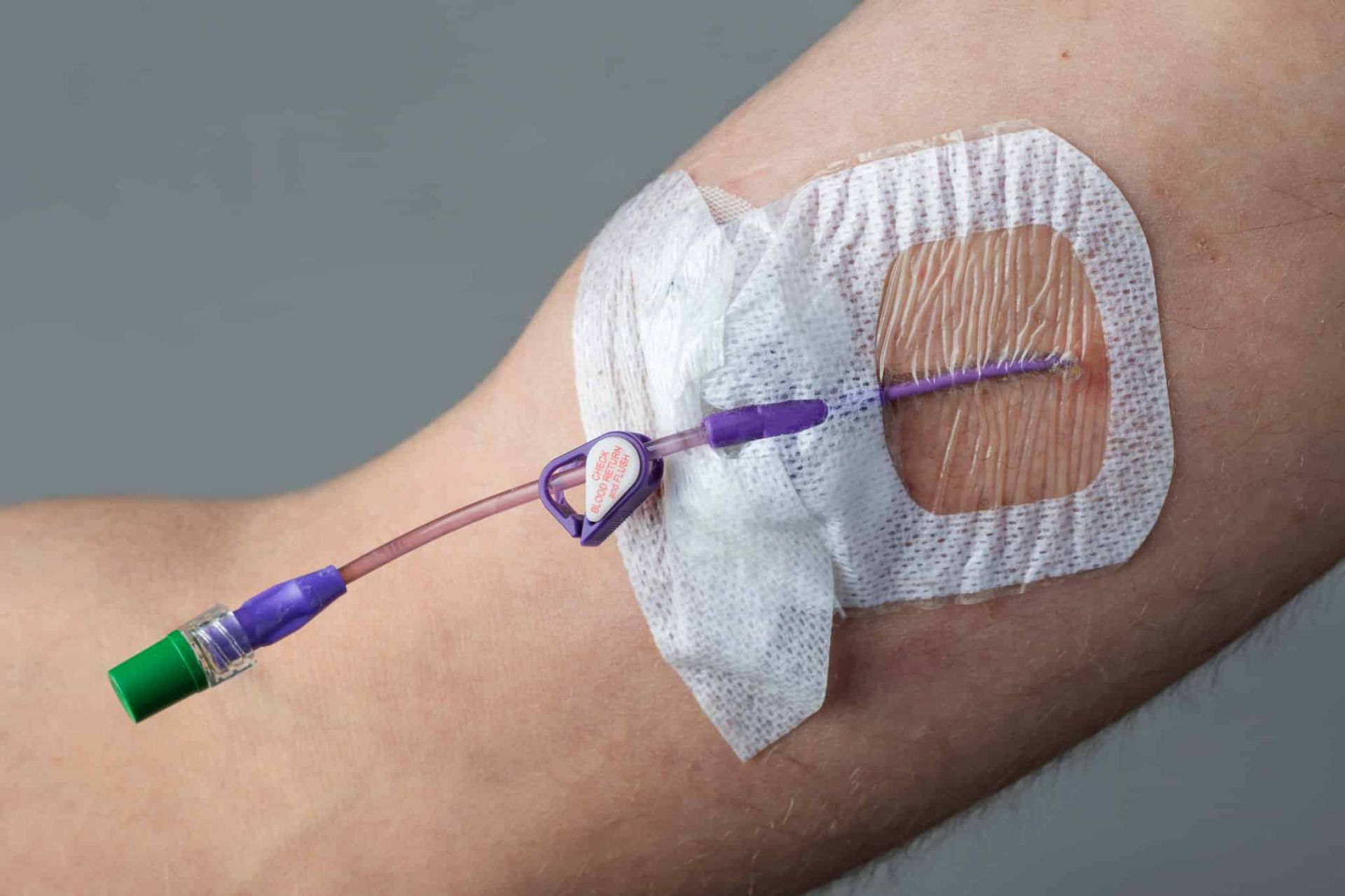

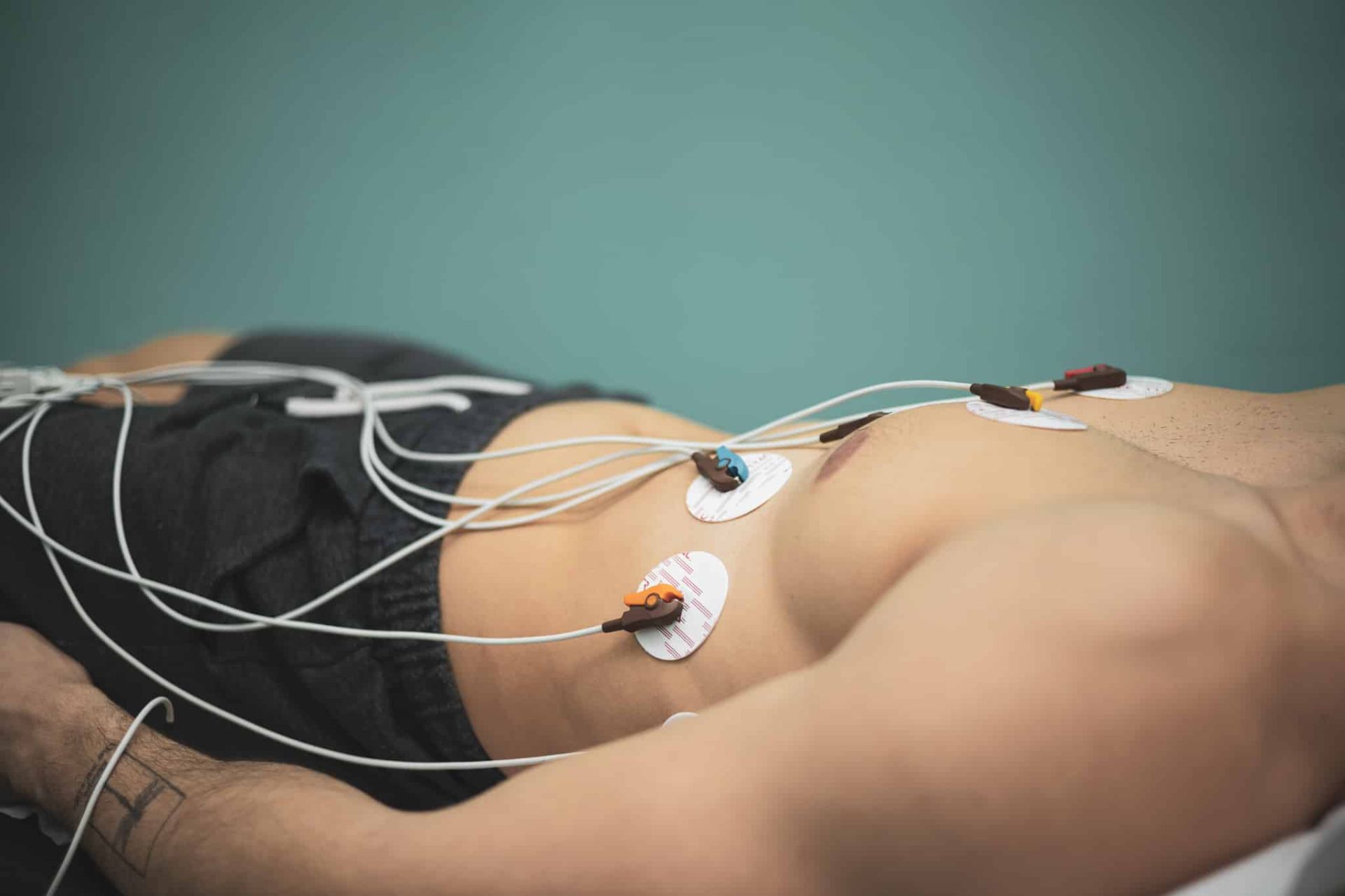

Healthcare Applications: Enhancing Medical Product

Precision with Flexible Dies

polarizer films, and FPC. These parts, commonly found in smartphones and smartwatches, demand seamless cutters,

high precision, and efficient roll-to-roll processing.

-

Glucose Test Strips

-

PICC Dressing

-

Electrode Patches

【Machine, Home Appliance and Automotive】

- Control Panel, Gaskets

-

Membrane Switch

-

Copper Ring Terminals

-

Micro Gasket

Sticker, Label and Office Supplies

-

Stamps

-

Envelopes

-

Sticker, Label