In accordance with the EU's implementation of the Personal Data Protection Act, we are committed to safeguarding your personal information and providing you control over it. We have updated and will regularly update our Privacy Policy to comply with this personal data protection law. Please refer to our latest Privacy Statement.

This website uses cookies to enhance your browsing experience. To learn more about how this website uses cookies, please click here.

Latest News

05.Aug.2025

Material Knowledge

Bending Issues and Countermeasures Part 1: Preventing Cracks During Bending

There is a relationship between bending and cracking, particularly between the material's rolling direction and the bending line. Bending perpendicular or at an angle to the rolling direction can help prevent cracking.

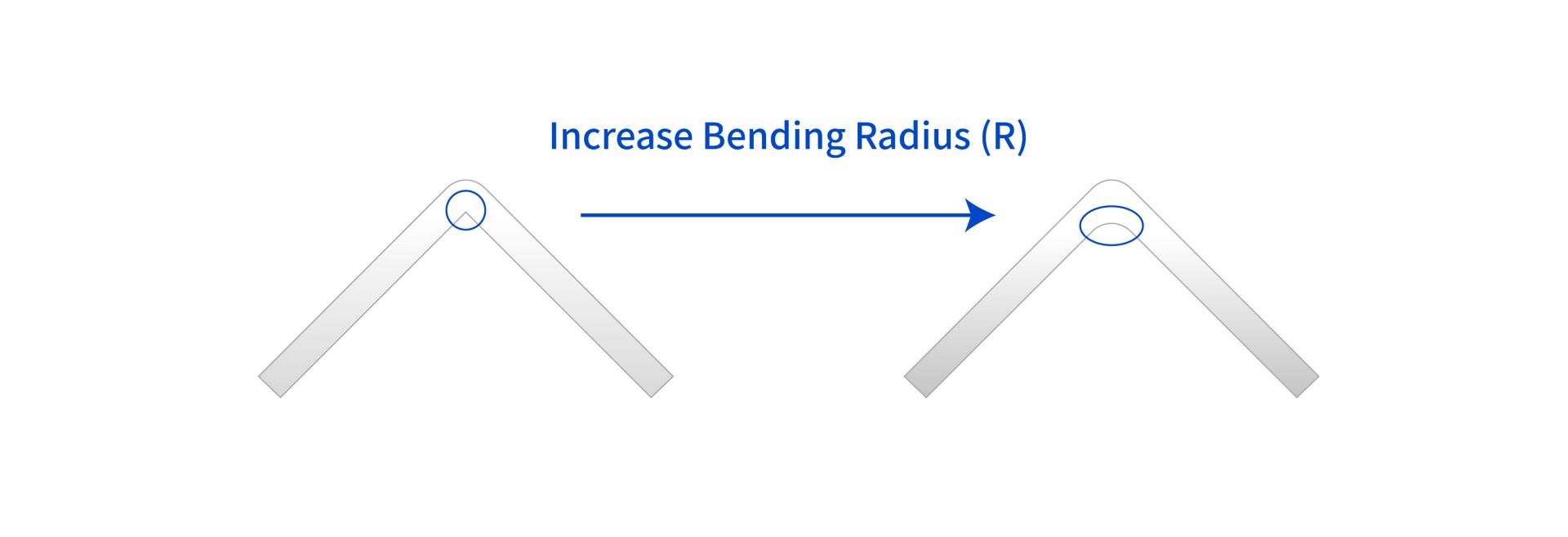

As shown in [Figure 1], increasing the bending radius is also an effective method. When the bending radius (R) is approximately five times the thickness of the sheet, further increases beyond that point will offer minimal improvement.

Cracks during bending tend to occur at the ends. This is often caused by surface roughness the rougher the surface, the higher the risk of cracking. This situation is typically seen when bending on the burr side.

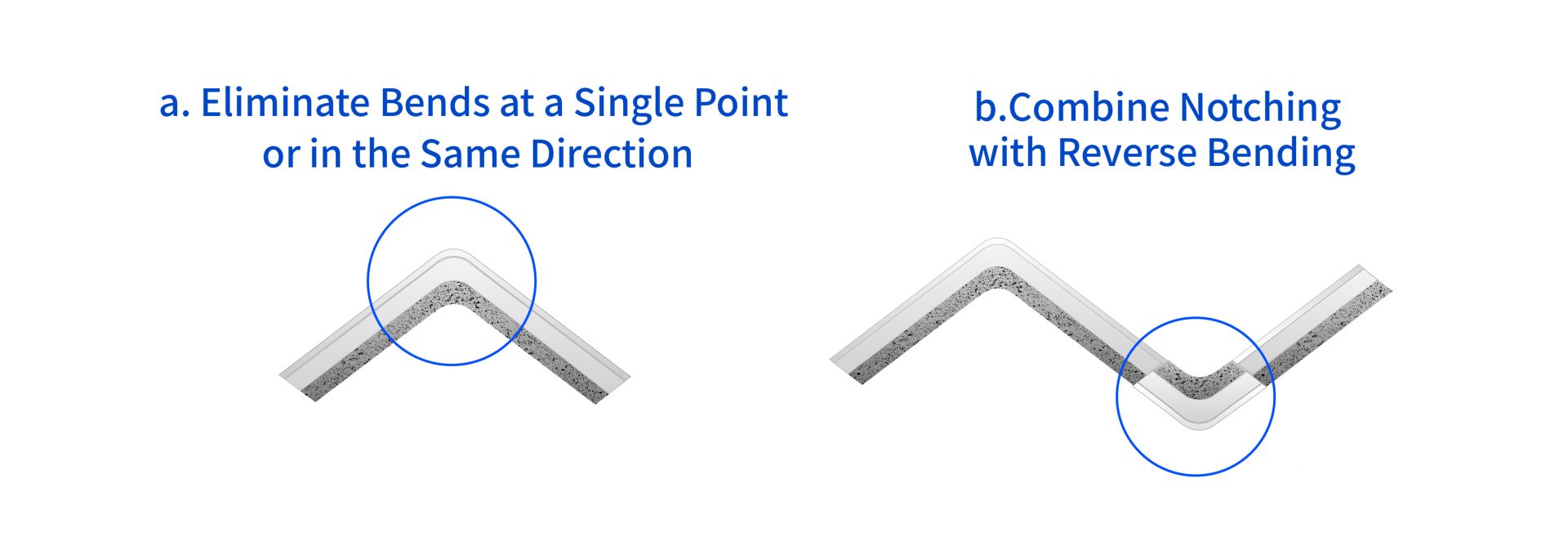

Therefore, as illustrated in [ Figure 2:a] , bending with the sheared (burr) side facing outward is effective. In products that require bending in both upward and downward directions, placing the burr on the outside for either direction helps eliminate burr-related cracks.

In such cases, as shown in[ Figure 2:b] , notching or similar treatments on the outer burr side can help ensure that the sheared surface is positioned on the outer bending side. This technique is especially useful when bending thin wooden boards or panels.

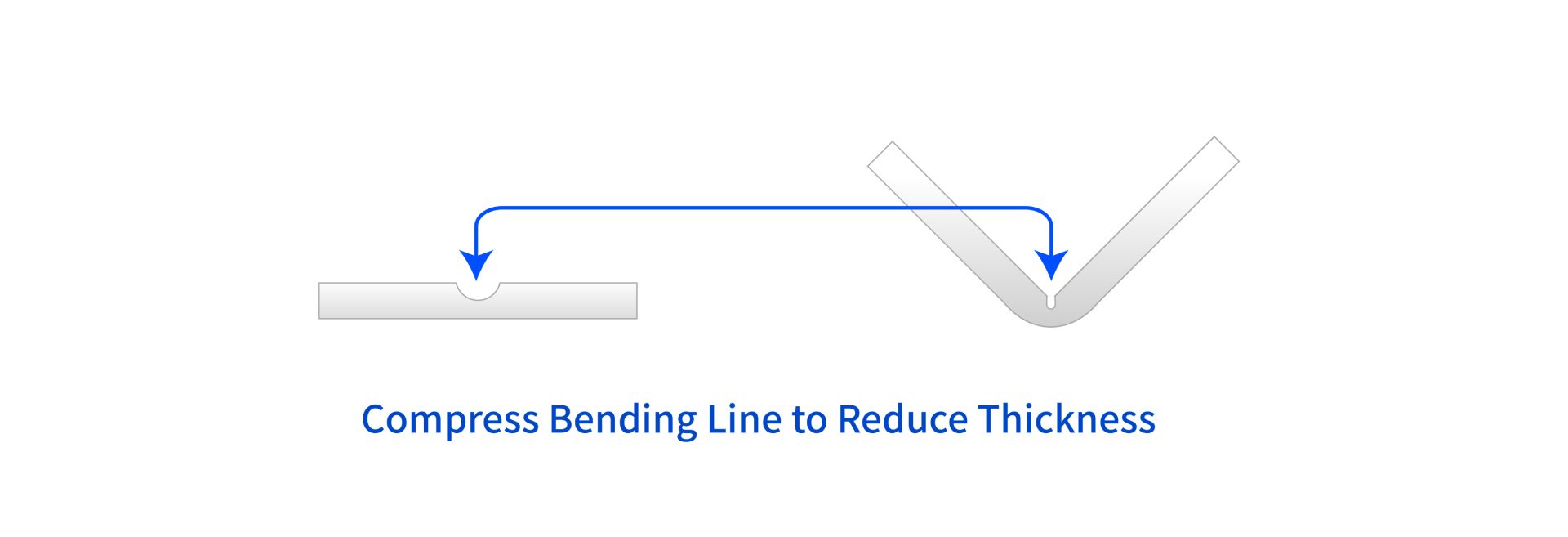

Cracking in thin sheets is relatively uncommon. The concept for achieving this favorable condition is shown in [Figure 3].

Another effective approach to prevent cracking is to apply a crushed layer along the bending line, thinning the material locally.

However, this comes with the trade-off of reduced strength in the bent section.

The content of this article is intended solely for technical reference and informational exchange.

Original source : https://jp.misumi-ec.com/tech-info/categories/press_mold_design/pr05/c0164.html

Some content has been adapted for better clarity and local relevance.

Other

30

Sep.2025

Material Knowledge

Stronger Steel Through the Right Direction - Hung Shuh Stands with You

28

Jul.2025

Material Knowledge

Introduction to Carbon Steel: Composition and Applications

28

Jul.2025

Material Knowledge