In accordance with the EU's implementation of the Personal Data Protection Act, we are committed to safeguarding your personal information and providing you control over it. We have updated and will regularly update our Privacy Policy to comply with this personal data protection law. Please refer to our latest Privacy Statement.

This website uses cookies to enhance your browsing experience. To learn more about how this website uses cookies, please click here.

Latest News

20.Jan.2026

Material Knowledge

Comparison of S65C, SK85, and SK95 for Strip Steel Applications

Characteristics, Applications, and Material Selection Guidelines for High-Carbon Steels

1. Introduction

Our company offers three grades of high-carbon steel for strip steel applications: S65C, SK85, and SK95.

Because springs, cutting tools, and precision components each require different mechanical properties,

understanding the characteristics of each steel grade is essential for proper material selection.

This article compares the key properties of these steels such as hardness, toughness, fatigue strength, and wear resistance and provides practical guidelines to support engineers and designers in making appropriate material choices.

2. Characteristics Comparison of S65C, SK85, and SK95 (Revised)

Steel Grade |

Steel Grade

|

Characteristics (Technical Perspective)

|

S65C |

• Easily forms martensite while being less prone to excessive hardening.

|

Springs, mainsprings, hinges, washers, spacers |

SK85 |

•Higher carbon content, offering a good balance between sharpness and elastic recovery.

|

Hand saws, cutters, clutch components, washers, spring |

SK95 |

•High-carbon steel capable of achieving the highest quench hardness.

|

cutters |

| Polish Finish | Chemical Conposion(%) | ||||||||

| JIS | SAE | C | Si | Mn | P | S | Cu | Ni | Cr |

| S65C | 0.60 ~ 0.70 | 0.15 ~ 0.35 | 0.60 ~ 0.90 | ≦0.030 | ≦0.035 | ≦0.30 | ≦0.20 | ≦0.20 | |

| SK85 | 0.80 ~ 0.90 | 0.10 ~ 0.35 | 0.10 ~ 0.50 | ≦0.030 | ≦0.035 | ≦0.30 | ≦0.20 | ≦0.20 | |

| SK95 | 0.90 ~ 1.00 | 0.10 ~ 0.35 | 0.10 ~ 0.50 | ≦0.030 | ≦0.035 | ≦0.25 | ≦0.25 | ≦0.30 | |

| SKS51 | 0.75 ~ 0.85 | ≦0.35 | ≦0.50 | ≦0.030 | ≦0.030 | ≦0.25 | 1.30 ~2.00 | 0.20 ~ 0.50 | |

| SKS5 | 0.75 ~ 0.85 | ≦0.35 | ≦0.50 | ≦0.030 | ≦0.030 | ≦0.25 | 0.70 ~ 1.30 | 0.20 ~ 0.50 |

3. Material Selection Guidelines

3.1 Required Hardness and Edge Retention

-

Cutting tools, hand saws, and blades (SK95)

-

Practical hardness range: HRC 50–55 (HV approx. 520–600)

-

Above HRC 55, the following issues increase significantly:

-

Reduced toughness

-

Processing cracks (micro-chipping during shearing or punching)

-

Chipping and fracture during service

Therefore, HRC 55 is generally considered the upper design limit.

-

-

The advantage of SK95 lies in its ability to easily achieve high hardness, providing stable edge retention and wear resistance around HRC 55.

-

Components requiring moderate hardness with toughness (SK85)

-

Practical hardness range: HRC 48–53 (HV approx. 500–560)

-

Offers a well-balanced combination of sharpness and impact resistance, making it suitable for applications where impact and wear coexist, such as hand saws, clutch components, and washers.

-

Components requiring high cyclic bending fatigue life (S65C)

-

Practical hardness range: HRC 42–50 (HV approx. 430–520)

-

Rather than excessive hardness, stability in cyclic bending fatigue life (S–N characteristics) is the critical factor for these applications.

3.2 Why Hardness Above HRC 60 Is Not Recommended

-

Although high-carbon steel (SK95) can theoretically reach HRC 60 through quenching:

-

Martensite becomes finer, reaching peak hardness while toughness drops sharply.

-

-

Hand saws and cutting tools are subjected to combined tensile, bending, and torsional stresses, greatly increasing the risk of brittle fracture.

-

In thin strip steels (0.1–3.0 mm), fracture during processing becomes more frequent:

-

Edge chipping during shearing

-

Cracking during slitting

-

Microcrack formation during bending

-

-

For these reasons, most manufacturing sites operate with HRC 55 as the practical upper limit.

Other

03

Nov.2025

Material Knowledge

Hardness Conversion Table

27

Jan.2026

Material Knowledge

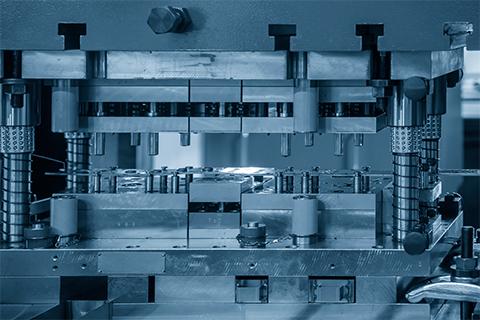

Differences in Materials for Press Stamping

08

Dec.2025

Material Knowledge