In accordance with the EU's implementation of the Personal Data Protection Act, we are committed to safeguarding your personal information and providing you control over it. We have updated and will regularly update our Privacy Policy to comply with this personal data protection law. Please refer to our latest Privacy Statement.

This website uses cookies to enhance your browsing experience. To learn more about how this website uses cookies, please click here.

HOME

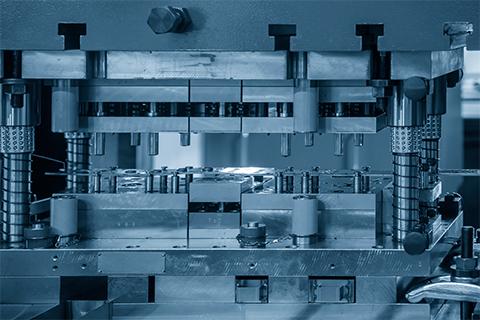

Material Knowledge The Secret of High-Precision Heat-Treated Steel Strips: Martempering and the Advantages of Our EBNER Continuous Heat Treatment Furnace

Latest News

30.Jan.2026

Material Knowledge

The Secret of High-Precision Heat-Treated Steel Strips: Martempering and the Advantages of Our EBNER Continuous Heat Treatment Furnace

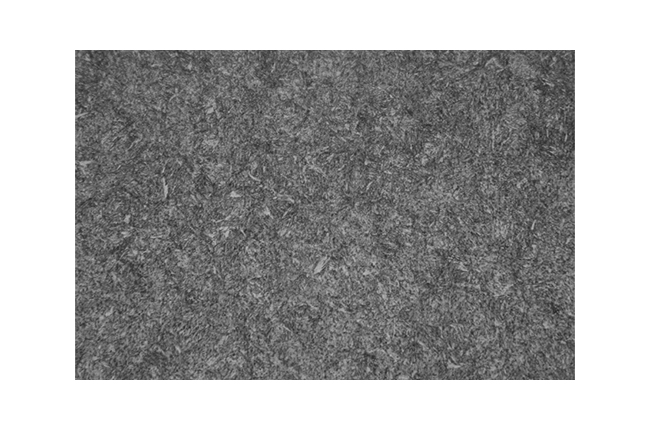

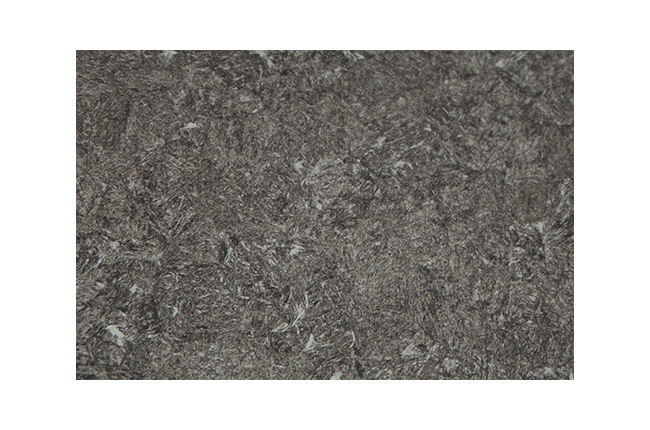

EBNER Heat Treating VS. Regular Heat Treating

-

EBNER Heat Treating

【 Coarse Grain 】 -

Regular Heat Treating

【 Fine Grain 】

1. The Performance of Special Steels (Carbon Steel / Carbon Tool Steel) Depends on Heat Treatment

Special steels are critical materials that directly affect the performance and durability of components.

In automotive parts and precision machinery, even small distortions or internal stresses can significantly

impact overall product reliability. Therefore, the choice of heat treatment is not just a processing step

It is key to ensuring product quality.

2. What is Martempering?

Martempering is a quenching process in which steel is first heated to form austenite,

then cooled to a specific temperature and held isothermally before being air-cooled to transform into a martensitic structure.

Features of Martempering

-

Reduces internal stress and cracking caused by rapid quenching

-

Produces a uniform and stable martensitic structure

-

Maintains high hardness while improving dimensional accuracy and durability

Compared to conventional quenching, martempering allows precise temperature control,

effectively minimizing internal stress and deformation in the steel.

3. Our Heat Treatment Equipment and Technical Advantages

We use state-of-the-art continuous heat treatment furnaces from EBNER (Austria), enabling stable and continuous martempering.

While martempering is an ideal heat treatment method, it requires extremely precise temperature control,

and many heat treatment companies are unable to implement it reliably.

Our process ensures low internal stress, minimal deformation, and consistently high-quality steel strips.

4. Applications and Customer Trust

A. Automotive Parts Manufacturers

Automotive parts demand extremely high reliability.

Our steel strips have passed stringent audits and are supplied continuously.

Precision heat treatment ensures the components remain stable and reliable in service.

B. Precision Machinery Components

The steel strips can meet flatness tolerances of 0.1% across the width.

In products composed of thousands to tens of thousands of parts, each part's precision directly affects overall quality.

Our steel strips meet these demanding requirements and are highly trusted by customers.

C. Hand Saw Steel

Some customers process the steel strips into final products and sell them under their own brands.

Direct feedback from users indicates excellent durability and cutting performance,

clearly demonstrating the reliability of our steel.

5. Conclusion

By combining continuous heat treatment furnaces with martempering,

we provide high-quality steel strips with low internal stress, uniform microstructure, and stable precision.

For customers seeking high durability, precise processing, and reliability,

we invite you to try samples or consult with our technical team to experience the advantages of our steel strips firsthand.

Other

03

Nov.2025

Material Knowledge

Hardness Conversion Table

29

Jan.2026

Material Knowledge

What Does the "M" in JIS Standard "SK85-M" Stand For?

27

Jan.2026

Material Knowledge