In accordance with the EU's implementation of the Personal Data Protection Act, we are committed to safeguarding your personal information and providing you control over it. We have updated and will regularly update our Privacy Policy to comply with this personal data protection law. Please refer to our latest Privacy Statement.

This website uses cookies to enhance your browsing experience. To learn more about how this website uses cookies, please click here.

Latest News

03.Dec.2025

Material Knowledge

Major Alloying Elements in Steel and Their Effects

The performance of special steels isgreatly influenced by the types and amounts of alloying elements they contain.

To help our customers better understand the characteristics of the steels wesupply, we have summarized the roles and effects of the principal elements.

This information may serve as a reference when considering processingconditions and product applications.

| Element | Main Function | Explanation & Notes |

|---|---|---|

| Carbon (C) | Increases strength and hardness | Carbon is the most significant element affecting the hardness and strength of steel. Higher carbon content increases hardness and tensile strength, but generally reduces toughness. During quenching—rapid cooling after heating—austenite transforms into martensite, resulting in higher hardness. Therefore, material selection should ensure that the hardness meets the requirements of the intended application. |

| Manganese (Mn) | Strengthening ; enhances hardenability | Manganese increases the strength of steel and improves hardenability by allowing deeper hardness penetration during quenching. It also combines with sulfur to stabilize impurities and reduce the risk of hot shortness. |

| Chromium (Cr) | Improves wear resistance and hardenability | Chromium raises the achievable hardness after quenching and enhances resistance to wear. In alloy steels and stainless steels, chromium also contributes to improved corrosion resistance. |

| Nickel (Ni) | Enhances toughness and corrosion resistance | Nickel provides excellent toughness at low temperatures and improves overall corrosion resistance, helping retain performance under demanding environmental conditions. |

| Molybdenum (Mo) | Enhances hardenability and wear resistance | Molybdenum promotes hardening and helps maintain strength after heat treatment. It also improves high-temperature strength and resistance to wear. |

| Silicon (Si) | Strengthening ; deoxidizing element | Silicon contributes to increased strength and acts as a deoxidizer during steelmaking. It helps improve the stability of steel properties during processing and heat treatment. |

| Sulfur (S) | Improves machinability | Sulfur enhances machinability, especially in cutting operations. However, excessive sulfur may reduce toughness, so understanding the steel's characteristics is important. |

| Phosphorus (P) | Strengthening | Phosphorus increases the strength of steel. If present in excessive amounts, it may cause embrittlement, so attention to material characteristics is necessary. |

⚠️Notes

-

The information above summarizes the general tendencies of each element's effect on steel.

-

Actual material performance varies depending on interactions among elements and heat-treatment conditions.

-

The steels supplied by our company are limited to specific grades.

-

Please understand the characteristics of each element and use the material safely and appropriately.

Other

03

Nov.2025

Material Knowledge

Hardness Conversion Table

27

Jan.2026

Material Knowledge

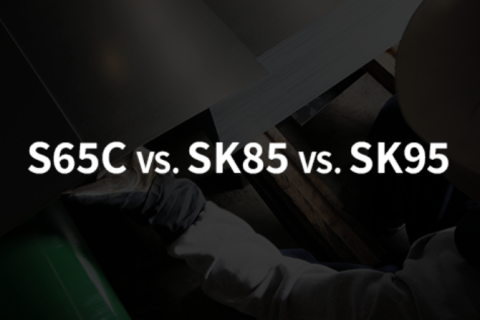

Differences in Materials for Press Stamping

20

Jan.2026

Material Knowledge