In accordance with the EU's implementation of the Personal Data Protection Act, we are committed to safeguarding your personal information and providing you control over it. We have updated and will regularly update our Privacy Policy to comply with this personal data protection law. Please refer to our latest Privacy Statement.

This website uses cookies to enhance your browsing experience. To learn more about how this website uses cookies, please click here.

Latest News

28.Jul.2025

Die Cutting knowledge

Die Cutting: Choosing the Best Cutting Rules and Materials

1.Intro:Briefly explain what die cutting is and its importance in various industries. Emphasize the role of cutting rules (steel rules) as the backbone of precise and efficient die cutting.

b. Applications: Key industries relying on die cutting, including:

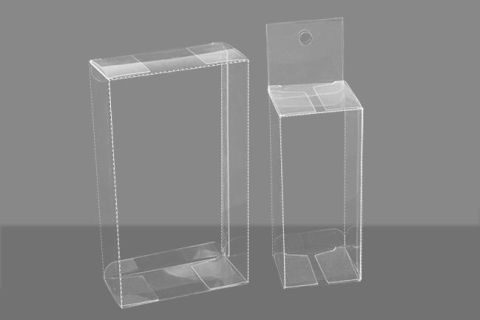

Packaging: Shaping cardboard and plastics.Electronics: Cutting precision components.Automotive: Creating gaskets and other intricate parts.

c. Highlight the need for accuracy and consistency in die cutting.

b. Flexible Steel Rules: When and why to choose flexible options for intricate designs.

c. Thickness and Edge Types: Discuss factors such as rule thickness and bevel options (center, single, double) for specific materials.

d. Key Considerations: Material being cut (cardboard, plastic, metal).Required precision and complexity of the cut.Cost vs. durability trade-offs.

b. Maintenance Practices: How regular inspection and sharpening ensure longevity and consistent performance.

c. Technological Innovations: Tools and methods to improve accuracy, such as laser cutting for rule preparation or advanced die technologies.

b. Automotive Industry: Creating heat-resistant gaskets and seals with thicker, durable materials.

c. Packaging Industry: Achieving clean and fast cuts for high-volume production.

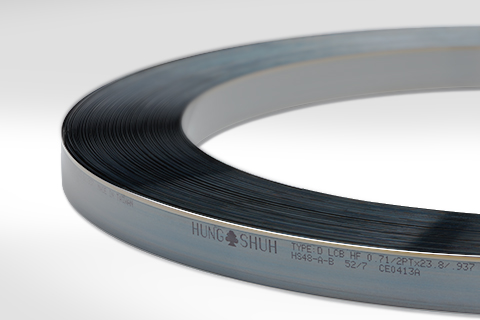

b. Hung Shuh’s expertise in providing cutting rules and die cutting solutions.

c. Conclusion: Elevate Your Die Cutting with Hung Shuh

2.Understanding Die Cutting: Principles and Applications

a. Principles of Die Cutting: How materials are cut or shaped using cutting rules and dies.b. Applications: Key industries relying on die cutting, including:

Packaging: Shaping cardboard and plastics.Electronics: Cutting precision components.Automotive: Creating gaskets and other intricate parts.

c. Highlight the need for accuracy and consistency in die cutting.

3.Choosing the Right Cutting Rule: Types and Benefits

a. High-Grade Steel Rules: Benefits of hardened and tempered steel in high-precision applications.b. Flexible Steel Rules: When and why to choose flexible options for intricate designs.

c. Thickness and Edge Types: Discuss factors such as rule thickness and bevel options (center, single, double) for specific materials.

d. Key Considerations: Material being cut (cardboard, plastic, metal).Required precision and complexity of the cut.Cost vs. durability trade-offs.

4.Enhancing Durability and Precision in Die Cutting

a. Edge Treatments: Benefits of treatments like chrome plating or nitriding to extend rule life.b. Maintenance Practices: How regular inspection and sharpening ensure longevity and consistent performance.

c. Technological Innovations: Tools and methods to improve accuracy, such as laser cutting for rule preparation or advanced die technologies.

5.Industry Applications: Tailored Solutions for Unique Needs

a. Electronics Industry: Cutting thin, sensitive materials with high precision.b. Automotive Industry: Creating heat-resistant gaskets and seals with thicker, durable materials.

c. Packaging Industry: Achieving clean and fast cuts for high-volume production.

6.Partnering with the Right Supplier for Die Cutting Success

a. Why a reliable supplier is crucial for quality and customization.b. Hung Shuh’s expertise in providing cutting rules and die cutting solutions.

c. Conclusion: Elevate Your Die Cutting with Hung Shuh

Other

25

Sep.2025

Die Cutting knowledge

Enhancing Fold Lines | The Essential Role of Creasing Rules

11

Sep.2025

Die Cutting knowledge

Why Do New Die Cutting Dies Deliver Fewer Cutting Cycles?

31

Jul.2025

Die Cutting knowledge