In accordance with the EU's implementation of the Personal Data Protection Act, we are committed to safeguarding your personal information and providing you control over it. We have updated and will regularly update our Privacy Policy to comply with this personal data protection law. Please refer to our latest Privacy Statement.

This website uses cookies to enhance your browsing experience. To learn more about how this website uses cookies, please click here.

Latest News

11.Sep.2025

Die Cutting knowledge

Why Do New Die Cutting Dies Deliver Fewer Cutting Cycles?

When a new die cutting tool seems to wear out too quickly, it often takes time to identify the real cause.

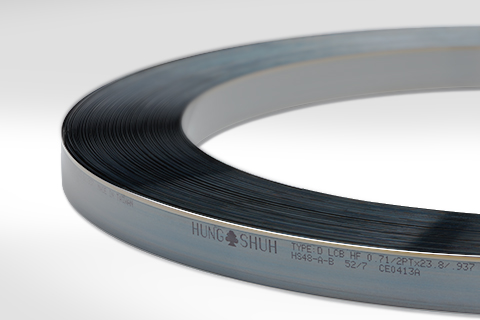

At Hung Shuh, every stage of our die manufacturing process includes strict inspection points to ensure quality. We recommend operators perform a basic visual check as soon as a new die is unpacked. If anything unusual is found, please contact your authorized Hung Shuh distributor immediately.

From laser-cutting the wooden base, bending the rules, assembling the parts, to final delivery for mass production, each step carries potential risks that may damage the cutting edge. Factors such as laser spacing, rule alignment, the accuracy of patching or filling in the die shop, machine setup precision, and pressure adjustments during production all of these can directly or indirectly affect the lifespan of the die.

We welcome the opportunity to work with you to identify the root cause of reduced cutting cycles. Customers are encouraged to share videos, photos, cut samples, or even the die itself, so we can analyze the situation and provide targeted support.

When using a new die, it’s important not to apply the same pressure settings used for older dies. The sharp edge of a brand-new tool is already capable of delivering excellent cutting quality without excessive pressure. As the edge naturally wears over time, adjustments can be made gradually based on actual conditions. This approach not only prevents premature edge damage but also helps reduce issues like paper jams and rough cutting edges.

► Learn More: Further Reading: Key Advantages of Steel Cutting Rules

► Learn More: Expert Guide to Selecting the Right Cutting Rule

Other

25

Sep.2025

Die Cutting knowledge

Enhancing Fold Lines | The Essential Role of Creasing Rules

31

Jul.2025

Die Cutting knowledge

Is a Harder Blade Tip More Durable? Hung-Shuh Tell You Choose Right

28

Jul.2025

Die Cutting knowledge