In accordance with the EU's implementation of the Personal Data Protection Act, we are committed to safeguarding your personal information and providing you control over it. We have updated and will regularly update our Privacy Policy to comply with this personal data protection law. Please refer to our latest Privacy Statement.

This website uses cookies to enhance your browsing experience. To learn more about how this website uses cookies, please click here.

PRODUCTS

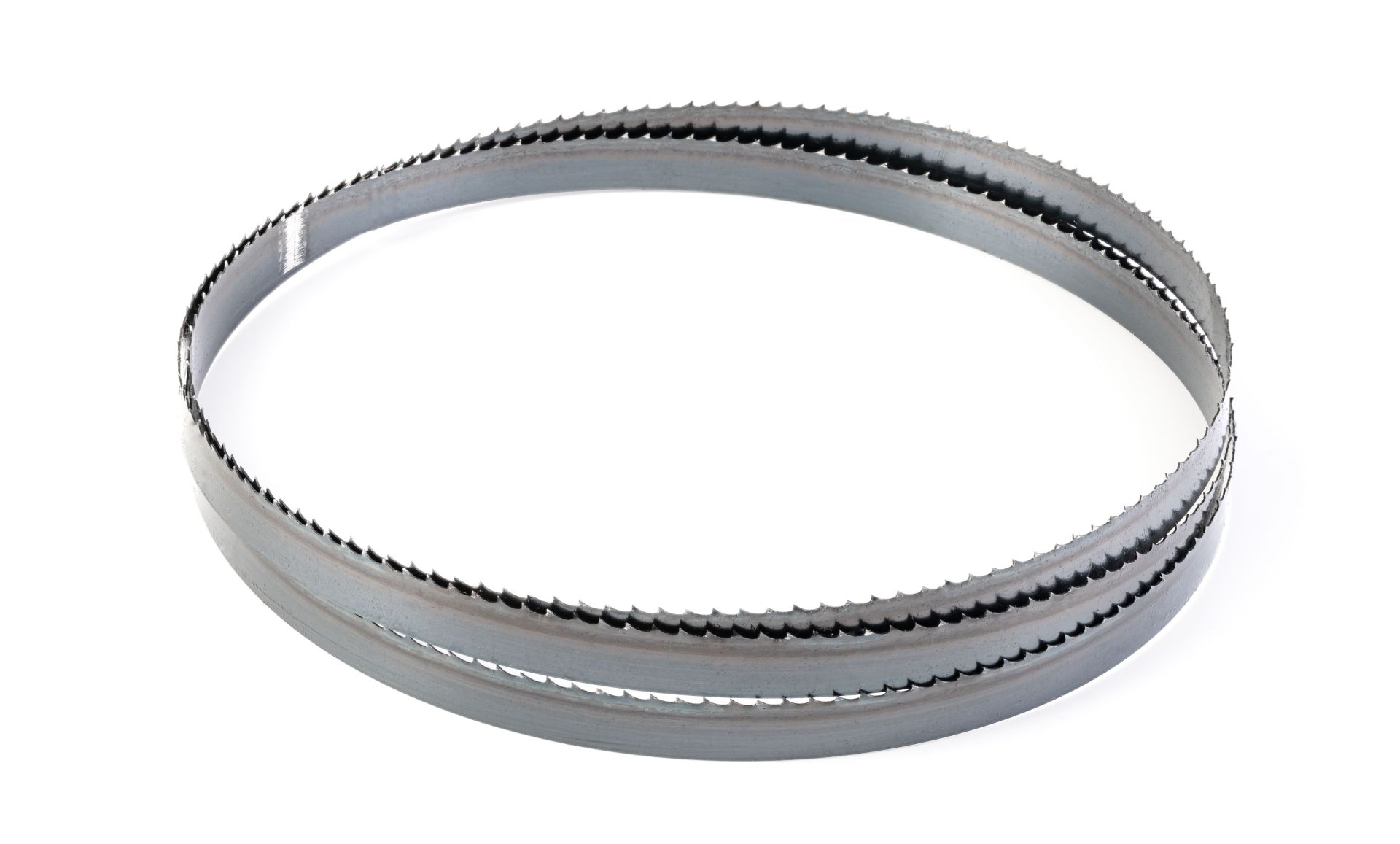

Band saw

Cutting process involves utilizing a continuous band-shaped saw blade, enabling precise straight or curved cuts. Commonly used materials for band saw blades include carbon tool steel and alloy steel, often combined with heat treatment processes to optimize the product. Frequently utilized steel types include SK85, SK95, 1085 steel, and the SKS series.

| Polish Finish | Chemical Conposion(%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| JIS | Nippon steel | C | Si | Mn | P | S | Cu | Ni | Cr |

| S65C | 0.60 ~ 0.70 | 0.15 ~ 0.35 | 0.60 ~ 0.90 | ≦0.030 | ≦0.035 | ≦0.30 | ≦0.20 | ≦0.20 | |

| SK85 | 0.80 ~ 0.90 | 0.10 ~ 0.35 | 0.10 ~ 0.50 | ≦0.030 | ≦0.035 | ≦0.30 | ≦0.20 | ≦0.20 | |

| SK95 | 0.90 ~ 1.00 | 0.10 ~ 0.35 | 0.10 ~ 0.50 | ≦0.030 | ≦0.035 | ≦0.25 | ≦0.25 | ≦0.30 | |

| SKS51 | 0.75 ~ 0.85 | ≦0.35 | ≦0.50 | ≦0.030 | ≦0.030 | ≦0.25 | 1.30 ~2.00 | 0.20 ~ 0.50 | |

| SKS5 | 0.75 ~ 0.85 | ≦0.35 | ≦0.50 | ≦0.030 | ≦0.030 | ≦0.25 | 0.70 ~ 1.30 | 0.20 ~ 0.50 |

| Polish Finish | Hardness | Tensile Strength(N/mm²) | ||

|---|---|---|---|---|

| JIS | Nippon steel | HV | HRC | |

| S65C | 320 ~ 560 | 33 ~ 53 | 1025 ~1950 | |

| SK85 | 340 ~ 580 | 34 ~ 54 | 1070 ~ 2020 | |

| SK95 | 340 ~ 580 | 34 ~ 54 | 1070 ~ 2020 | |

| SKS51 | 340 ~ 580 | 34 ~ 54 | 1070 ~ 2020 | |

| SKS5 | 340 ~ 580 | 34 ~ 54 | 1070 ~ 2020 |

RECOMMENDATION

Hand saw

Hardened and Tempered steel with polished

Circular saw

Hardened and Tempered steel with polished

Pneumatic Tools

Hardened and Tempered Steel Strip with Polished White